Warren Times Mirror and Observer- May 26, 1973, by Larry Stoltz

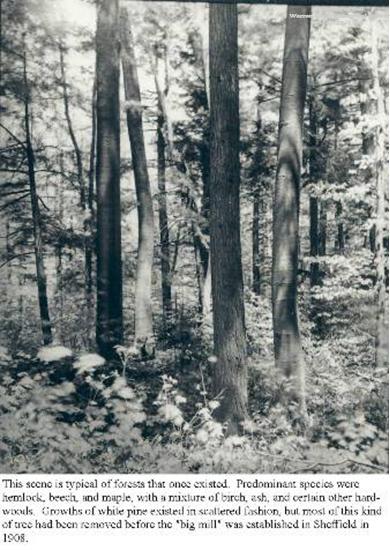

Early logging in the area that is presently the Allegheny National Forest was concentrated mainly on a single species—Eastern White Pine. The earliest logging of this species was confined to areas that were within easy skidding distances of the Allegheny River and its main tributaries. Fortunately, the best pine stands occurred close to the very streams down which lumber could be rafted to distant markets.

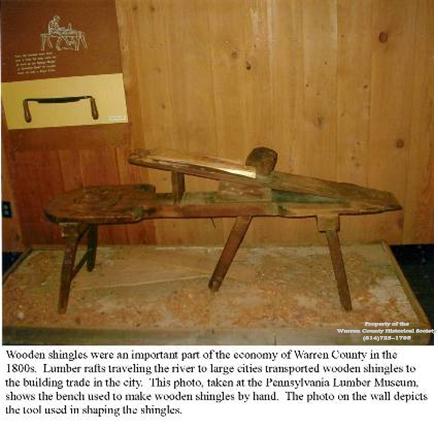

The first sawmill in Warren Country was established in 1800. It was an overshot wheel water-powered mill. Pine timbers from this mill were rafted to Pittsburgh in 1801. This may well have been the first lumber raft to float down the Allegheny, ushering in the great rafting days which formed such a colorful part of the early logging era. By 1820, Tionesta Creek, which drains the heartland of the Allegheny National Forest, had 21 sawmills along its banks.

In the early days of logging it was a common sight each spring to see the larger streams filled with rafts of lumber waiting for high water to carry them to market, sometimes as far as New Orleans. Some of the rafts of lumber that floated down the Allegheny River were 250 to 300 feet long, and 60 to 70 feet wide. Fleets of rafts set out from Warren with groups of 30 rafts making up the fleet.

Up until 1850, white pine continued to be the leading species cut in the area. Then hemlock began to be cut for its bark, to be used in tanning leather, while the logs were left to rot in the woods. As white pine became scarcer, hemlock lumber made its appearance. Still, logging of either species in any quantity remained concentrated in the valleys of the larger streams where water transport was feasible. Along the smaller streams, vast amounts of white pine remained.

After 1860, exploration to connect logging railroads made even the most isolated timberlands accessible and assured a year-round supply of logs for the hungry sawmills that soon sprang up.

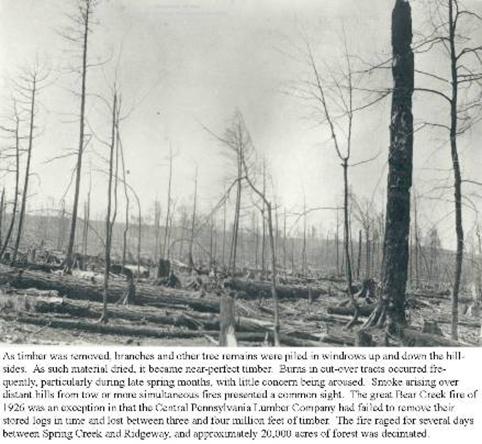

Railroad logging aided and abetted the “cut and get out!” policy of the early Pennsylvania lumbermen. Investments in rolling stock, and the cost of building the railroad grades and laying the track were high. Huge band mills, instead of water driven peckerwood sawmills, were set up to assure that enough milling capacity was on hand to saw into lumber all the logs that the logging trains could deliver. These band mills had rated capacities of 30 to 40 million board feet annually.

The big lumber companies which operated within the present boundaries of the Allegheny National Forest during the logging railroad era were Central Pennsylvania Lumber Company, Wheeler and Dusenbury Lumber Company, and T.D. Collins Lumber Company.

In 1903, the Central Pennsylvania Lumber Company installed a big steam and electrically powered band saw mill at Sheffield. It had a rated capacity of 130,000 board feet of lumber daily. But its all-time production record was on March 14, 1923, when 337,000 board feet of lumber were sawed in a ten-hour period. Between 1908 and 1941, when the C.P.L. closed down because of lack of timber, some one and a half billion board feet of lumber were sawed there.

The job of getting the logs from the woods to the logging railroad was done by horses. In the winter months, trail skidding of up to 25 logs at a time over snow-covered ground was accomplished over distances of up to a mile with horses. For greater distances, the logs were sledded to the railroad. They were loaded onto sleds from airways located at sled height. In the long winters of those days, there have been as many as 100 days of good sledding in a single winter.

In the summer, peeled hemlock logs were skidded and hauled to the logging railroad. The peeling season for hemlock lasted from May 15 to July 4. The first job after the hemlock logs were peeled was getting the bark to the railroad. Most of it was hauled on bark drays by teams, but some was hauled on wagons.

After the loggers had taken out the saw logs, the chemical wood cutter moved in and cleaned up the rest. They took the “blood, guts, and feathers” of the tree world—cull logs, standing cull trees, top-wood, and all trees left standing that were too small or too crooked for sawings.

It was this final cleanup by the chemical wood cutters that set the stage for the second generation forest, in which the valuable black cherry makes up such a large percentage of the stands on the Allegheny National Forest today.

Additional Resources:

Courtesy of the Warren County Historical Society